목차

토글Introduction

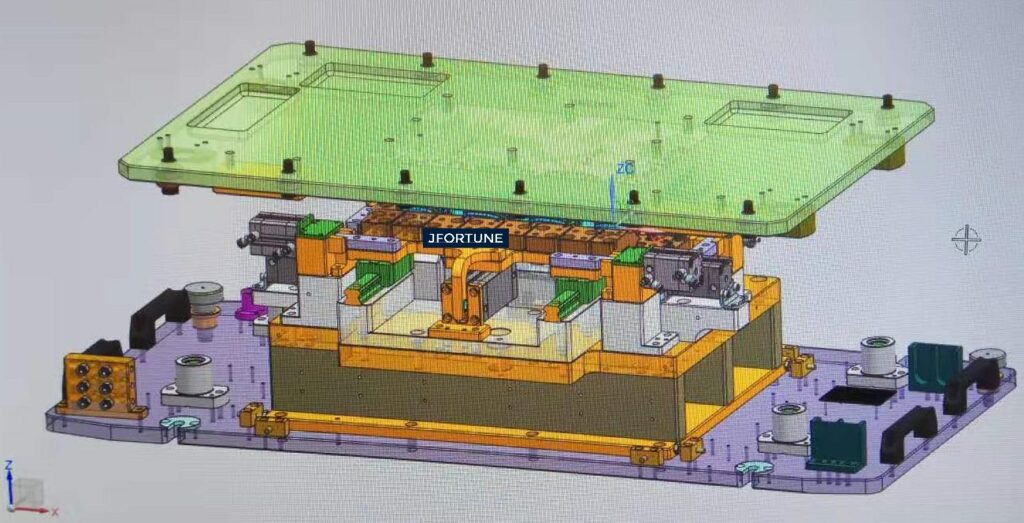

In the automotive industry, where efficiency and performance are paramount, the intake manifold plays a crucial role in engine functionality. The need for precision welding has led to the development of the intake manifold vibration welding machine. This advanced equipment offers consistent, high-quality welding for plastic intake manifolds, ensuring seamless assembly and optimal engine performance. Here’s an in-depth look at how it works and why it’s a must-have in automotive manufacturing.

Understanding Vibration Welding

Vibration welding is a process that joins plastic parts by generating frictional heat through controlled, linear vibrations. Here’s a quick overview:

- Alignment: The two plastic components are aligned under pressure.

- Vibrational Movement: One component vibrates horizontally at high frequency while the other remains stationary.

- Heat Generation: The frictional heat softens and melts the plastic at the contact points.

- Bond Formation: After the vibrations stop, the melted plastic solidifies, forming a strong weld.

Key Features of the Intake Manifold Vibration Welding Machine

1. Precision Welding Control

- Pressure and Frequency Control: Advanced control over vibration frequency and welding pressure ensures precise and uniform welds.

- Real-Time Monitoring: Sensors monitor welding parameters in real time, providing data for consistent quality control.

2. Automated Welding Process

- Automated Alignment: The machine automatically aligns and clamps the components in position for welding.

- Welding Cycle Automation: The entire welding process is automated, minimizing human error and maximizing productivity.

3. Compatibility with Various Intake Manifold Designs

- Multiple Manifold Types: The machine can accommodate different intake manifold designs and sizes.

- 재료 호환성: Suitable for welding a wide range of thermoplastics commonly used in intake manifolds, such as nylon and polypropylene【source needed】.

4. Structural Strength and Durability

- Robust Construction: The machine is designed for continuous use in high-demand production environments.

- Long Lifespan: High-quality materials and components ensure durability and reduce maintenance needs.

5. Fast Parameter Changeover

- Parameter Storage: Stores multiple welding parameter sets for quick changeover between different manifold types.

- 3-Second Retrieval: Parameters can be retrieved in as little as 3 seconds, maximizing efficiency.

Benefits of the Intake Manifold Vibration Welding Machine

1. High-Quality Welds

- Strong Bonds: The vibration welding process creates strong, reliable bonds ideal for high-pressure intake manifolds.

- Consistent Quality: Real-time monitoring and automated control ensure consistent weld quality across production batches.

2. Increased Efficiency

- Automated Process: Reduces production time and increases output by minimizing manual intervention.

- Quick Parameter Changeover: Fast retrieval of stored parameters minimizes downtime during changeover.

3. Versatility and Compatibility

- Multiple Manifold Designs: Compatible with a wide range of intake manifold designs and thermoplastic materials.

- Future-Proof: Easily adaptable to new manifold designs as the automotive industry evolves.

결론

The intake manifold vibration welding machine offers precision, efficiency, and durability in automotive manufacturing. Its automated, real-time welding process ensures high-quality bonds, crucial for maintaining engine performance. With fast parameter changeover, versatile design compatibility, and real-time monitoring, this machine provides manufacturers with a reliable, efficient solution for intake manifold assembly.

If you’re in the automotive industry or looking to upgrade your welding process, consider the intake manifold vibration welding machine. It’s a worthy investment that will improve your production quality and efficiency. Reach out for more information or to discuss how it can fit into your manufacturing setup!