Project Management

1. Project kick-off meeting (Between Customer & Jfortune)

1. introduction of project members (of both parties)

2. review the information still missing from the technical confirmation (release time of freeze data, special requirements of the factory, etc.)

3. review the project schedule: backward planning before T1 and nodal times for delivery of samples, shipment, and arrival at the factory after T1

Input: Technical Confirmation, Project Schedule

Activity: Review meeting

Output: Meeting minutes with corresponding responsible person / completion date

2. Data Confirmation

1. Customer issues data through their platform

2. Confirm the data version by email

3. Each version of data should be recorded by Jfortune’s project staff, recording the data version number and the time of receipt, and the data version number must be confirmed by email before the design is produced.

3. Jfortune internal project initiation meeting

1. Internal confirmation of design direction and technical issues by relevant sales, project and technical staff

2. Start the design

The objectives of this kick-off meeting were to

1. pull these related personnel to fully understand the customer’s technical requirements and share previous lessons learned.

2. With the premise that the program and customer nodal time are approved as feasible, the design department will develop a detailed design plan, staff time schedule, including procurement of key parts. So that you can track yourselves in place and the actual completion date is recorded on the document. For more than 3 days, report to project manager and sales. More than 5 days to report to the business manager to determine the follow-up remedial measures

3. update the project schedule to the customer PTE and procurement on a weekly basis (based on the updated status of the design schedule)

4. if the customer proposes a design change, there is a significant amount of change (time, price, risk of failure), must be alerted by email/ppt. Both parties confirm the new design and the new project schedule. Remember not to just verbally discuss and confirm without sending a record.

5. the design process fully reflects the standardization and design automation, saving design time and reducing the error rate.

4. PO issues

1. Confirm receipt of the PO issued by the customer

2.Confirm PO and provide invoice for customer to arrange payment

5.Design Phase Tracking

1. On the design progress, hold a brief weekly conference call with the client PTE to confirm

2. Communicate in a timely manner as much as possible to avoid delays

6. Design Review

1. The first round of design review can be conducted with the customer PTE first

2. The second round of design review needs to involve the customer’s factory and HSE

3. The design review should be conducted within 1-2 weeks if possible.

4. Face-to-face communication is possible if possible.

5. After the design review, both parties sign a document confirming the review.

6. For exported equipment, third party confirmation of the design if is required for CE certification.

7. Jfortune internal design confirmation

Jfortune internal project related person in charge to confirm, to ensure that the design has no problems, if there are problems need to confirm with the customer feedback in a timely manner.

8. Design data freezing and drawing issuance

1. After the final design data is approved by the customer, the drawings can be issued to the production department

9.Progress Feedback

Provide feedback to the customer the progress of the current project at a fixed time every week with relevant pictures.

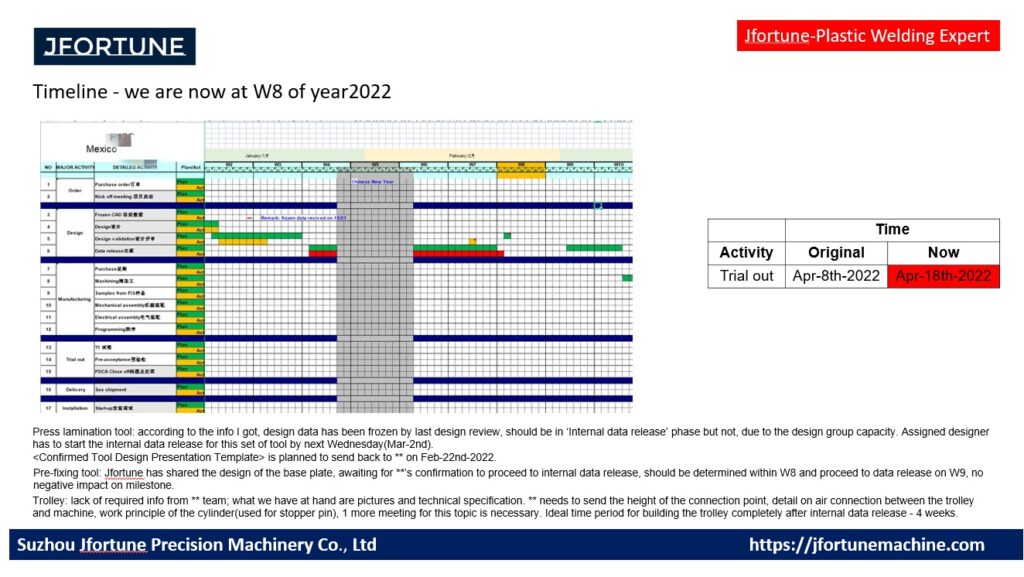

10.On the generation of delay issues

Once the delays are generated, the technology needs to communicate with the customer to provide an effective solution and how to make up for it in the following process to catch up with the T0 time

11. Payment

Confirm payment with the customer side according to the PO terms

12. Equipment sample

Confirm the sample time with the customer and do all the preparation work before the sample

13.Coordinate the arrangement of trial samples

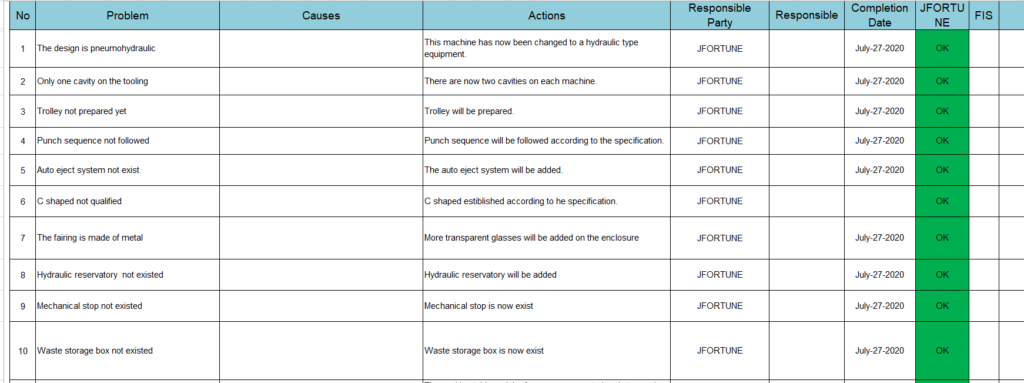

- Record the problem points raised by customers

- Reach consensus with customers and internal company on each issue on the problem list and give a deadline for completion

- Confirm the completion of PDCA and close all problems on schedule

- Keep records of parts shipped for trial production, including date, version and quantity, etc.

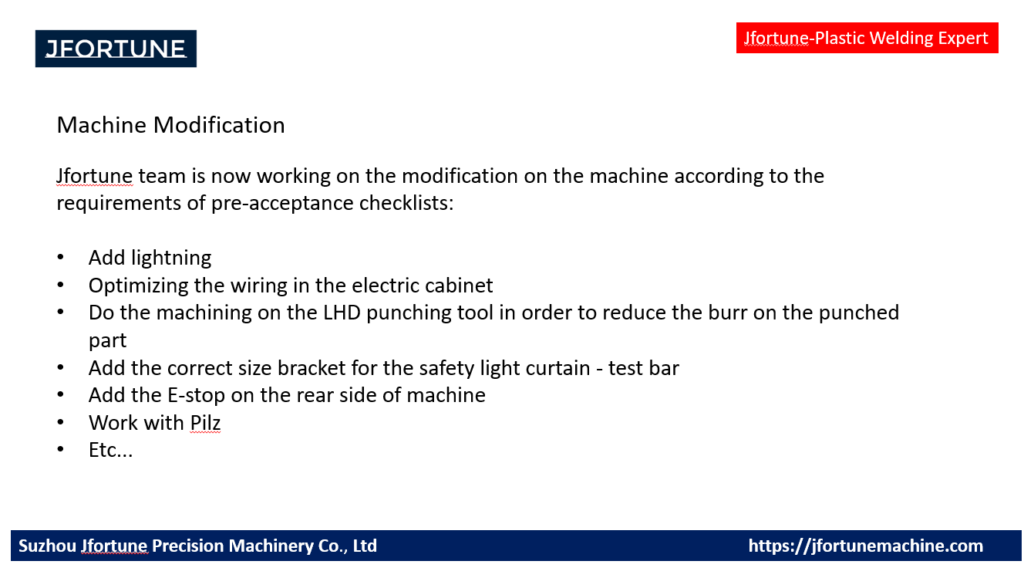

14. Acceptance problem point closure

1. Timely feedback on PDCA closure, with a picture format

2. PDCA closure needs to be confirmed by the customer

3. Ensure that the time to close the problem is timely

4. The exported equipment needs CE certified third party to check the operation condition of the equipment and give the list of problem points, and the Jfortune will make rectification against the list of problem points, and the third party needs to confirm the factory again after the rectification

15. Equipment shipment

1.Arrange the shipment according to the final time agreed with the customer

2. Confirm that the payment has been received from the customer according to the contract before shipment

3. Coordinate the time of equipment and personnel into the factory, and communicate with the customer to confirm

16 Equipment installation and commissioning after arrival at the factory

1. Organize the list of problematic points during installation and commissioning in the factory

2. And reach consensus with customers and internal company on the problem points

3. Close all the problem points on time

4. The customer completes the acceptance of the equipment at the factory

Quality verification before shipment should be documented. (HSE, Qualification Tracking sheet, PDCA update signature)

Installation and commissioning in the factory, acceptance confirmation OK to be recorded (HSE, Qualification Tracking sheet, PDCA update signature)

New problems found in the factory should be photographed and documented, and analyzed and summarized upon return.

17. Provide relevant information for equipment shipment

1. Operation manual

2. Circuit diagram, air circuit diagram

3. Spare parts list

4. CE certificate required for exporting equipment if needs

18. After-sales service and final acceptance

1.Follow up the after-sales service of the project

2. Complete the final acceptance of the equipment

19. Summary of experience

At the end of the project, the project leader’s side needs to issue a project summary report with all the PDCA documents and send it to all project-related leaders.