Plastic Welding Solutions for Automotive Lighting

You are required to create expansive lighting installations that are multi-dimensional and progressively intricate, seamlessly blending aesthetics, elegance, and practicality.Automotive lighting components are evolving into more intricate designs, such as tail lights that can extend up to a meter in length while seamlessly integrating delicate sensors, showcasing the growing complexity of these elements.Your ability to succeed relies on assisting today’s automakers in bringing to market sleek, elegant, and striking new designs. These vehicles must captivate potential drivers, fulfilling their desire for innovation and cutting-edge aesthetics. Lighting plays a crucial role in achieving these objectives in modern automobiles, ranging from sophisticated one-piece center tail lamps with intricate multidimensional shapes to subtle interior mood lighting that enhances the cockpit’s ambiance, creating a more inviting and comfortable environment.

You are required to create expansive lighting installations that are multi-dimensional and progressively intricate, seamlessly blending aesthetics, elegance, and practicality.Automotive lighting components are evolving into more intricate designs, such as tail lights that can extend up to a meter in length while seamlessly integrating delicate sensors, showcasing the growing complexity of these elements.Your ability to succeed relies on assisting today’s automakers in bringing to market sleek, elegant, and striking new designs. These vehicles must captivate potential drivers, fulfilling their desire for innovation and cutting-edge aesthetics. Lighting plays a crucial role in achieving these objectives in modern automobiles, ranging from sophisticated one-piece center tail lamps with intricate multidimensional shapes to subtle interior mood lighting that enhances the cockpit’s ambiance, creating a more inviting and comfortable environment.

Manufacturers like you face formidable obstacles in producing these assemblies. Fortunately, Jfortune’s automotive lighting welding technology are equipped to meet these challenges with technologically advanced solutions tailored to the specific demands of these applications. Increasingly complex automotive lighting applications made possible by advanced plastics welding processes.

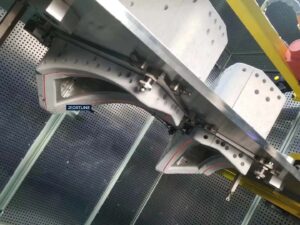

Once purely functional, automotive lighting applications are now elements of style and design, requiring welders that allow for delicate sensors, larger components with complex geometries, and flash-free welds — like Jfortune Clean Joining Technologies.

Clean welding creates particulate-free, high-strength bonding on aesthetically complex assemblies When it comes to meeting the challenges posed by cutting-edge automotive lighting, there is a technology— Clean Vibration Technology— stand out for their ability to create beautiful welds, free of “angel hair,” particulates and flash.

In addition, you get:

- High-strength bonds

- Hermetic seal prevents air and water intrusion

- Delicate electronics less likely to be damaged during assembly

- Ability to join more sensitive, challenging polymers

- Design freedom for complex shapes and contours

“Clean” has emerged as the pivotal concept in vibration welding, particularly in the realm of demanding automotive lighting applications. Clean Vibration Technology provides manufacturers with notable advantages. Unlike traditional vibration welding, where heat is generated through intense friction between the two components being welded, it follows a two-step process. First, a metal foil infrared emitter preheats the joint surfaces, and then the two parts are gently brought together under pressure and vibration to finalize the welding process. The resulting weld is devoid of particulate matter, and in certain materials, the weld joint experiences reduced stress, resulting in enhanced strength.

“Clean” has emerged as the pivotal concept in vibration welding, particularly in the realm of demanding automotive lighting applications. Clean Vibration Technology provides manufacturers with notable advantages. Unlike traditional vibration welding, where heat is generated through intense friction between the two components being welded, it follows a two-step process. First, a metal foil infrared emitter preheats the joint surfaces, and then the two parts are gently brought together under pressure and vibration to finalize the welding process. The resulting weld is devoid of particulate matter, and in certain materials, the weld joint experiences reduced stress, resulting in enhanced strength.

A comprehensive clean vibration welding portfolio for small to very large parts welders have been proven in lighting applications requiring superior aesthetics and rugged performance.

A comprehensive clean vibration welding portfolio for small to very large parts welders have been proven in lighting applications requiring superior aesthetics and rugged performance.

- Emitter specifications matched to each material’s absorption characteristic for increased energy efficiency

- Can be used to weld large complex shape