Table of Contents

ToggleEquipment layout and composition

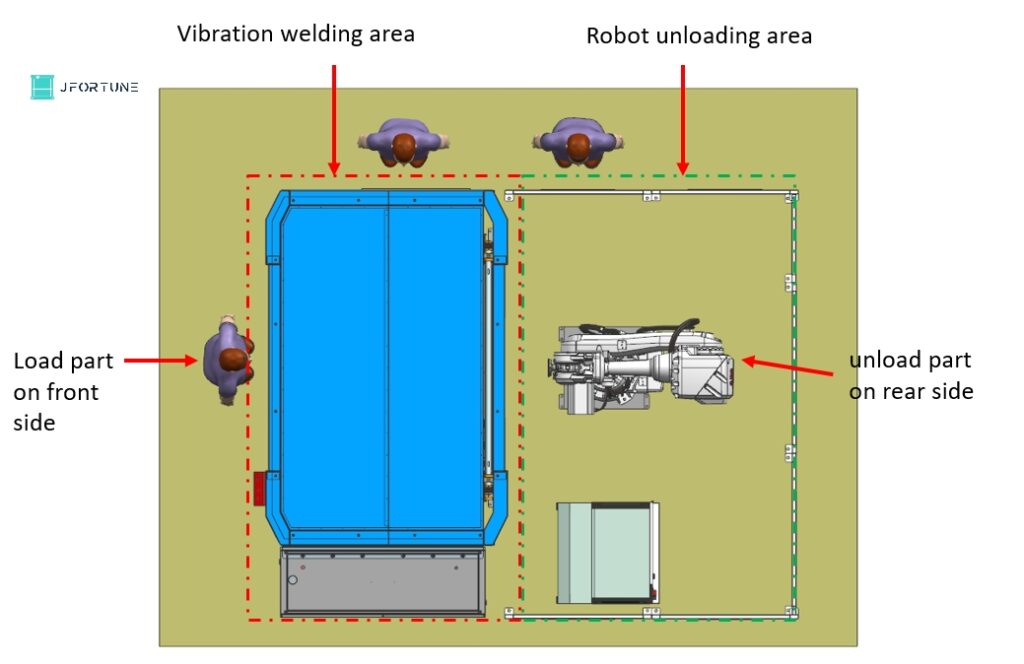

- The robot vibration welding machine is divided into two parts: vibration welding area and robot unloading area.

2. Equipment flow: manually put the product into the vibration machine on the front side—after the welding is completed, the robot unload the product and puts it on the production line.

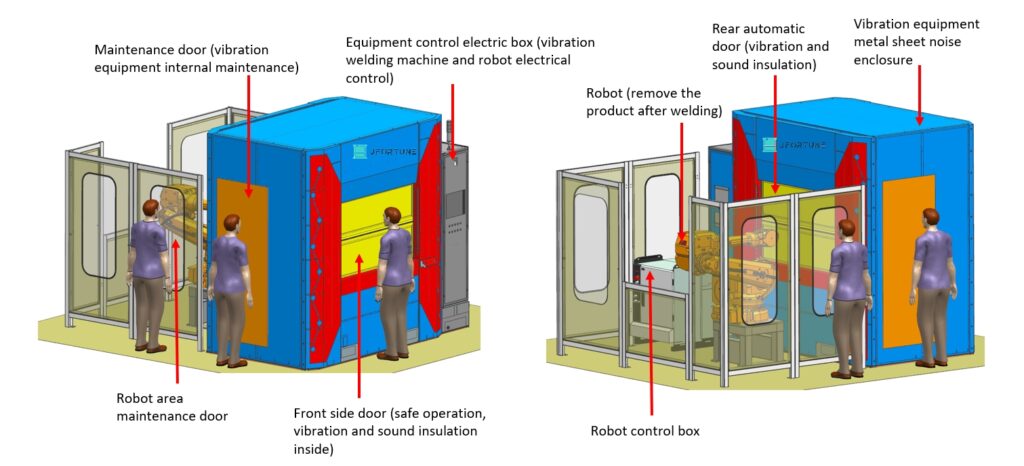

Machine outside

Welding process

The robot vibration welding machine whole process: manually put the product into the lower nest of the vibration equipment. – Start switch – scan code gun to test the product – front side door which is driven by servo motor safely closed – table servo motor drive lower table rises—the vibrating head starts to vibrate—the table servo drive lower table down—the servo motor of rear side door drives it open—the robot unloads product out of lower table—the rear side door servo motor drives it to close —The robot puts the product into the rear production line

The robot vibration welding process is like a well-orchestrated dance between humans and machines. It all begins when a person places a product into a special area of the machine. They then press a button to start everything.

A special scanner checks the product to make sure it’s good to go. Once that’s done, a door at the front of the machine closes gently using a motor. This door keeps everything safe inside.

Next, a part of the machine moves up, lifting the product. At the same time, a vibrating tool starts to shake things. This shaking helps the product’s parts to stick together really well.

When the shaking is finished, the machine part moves down, and a door at the back opens. This door lets a robot come in. The robot carefully takes the product and goes out of the machine. After that, the back door closes again.

The robot then goes to a different place where more work happens. It places the product where it needs to be for the next steps in making it. This whole process shows how people and robots can work together to make things just right. It’s like a dance of technology that turns separate parts into a strong and finished product.

Vibration head system

The vibrating head is composed of four sets of beam springs and two sets of electromagnets and drive plates. The vibration head system must match the standard tool to run.