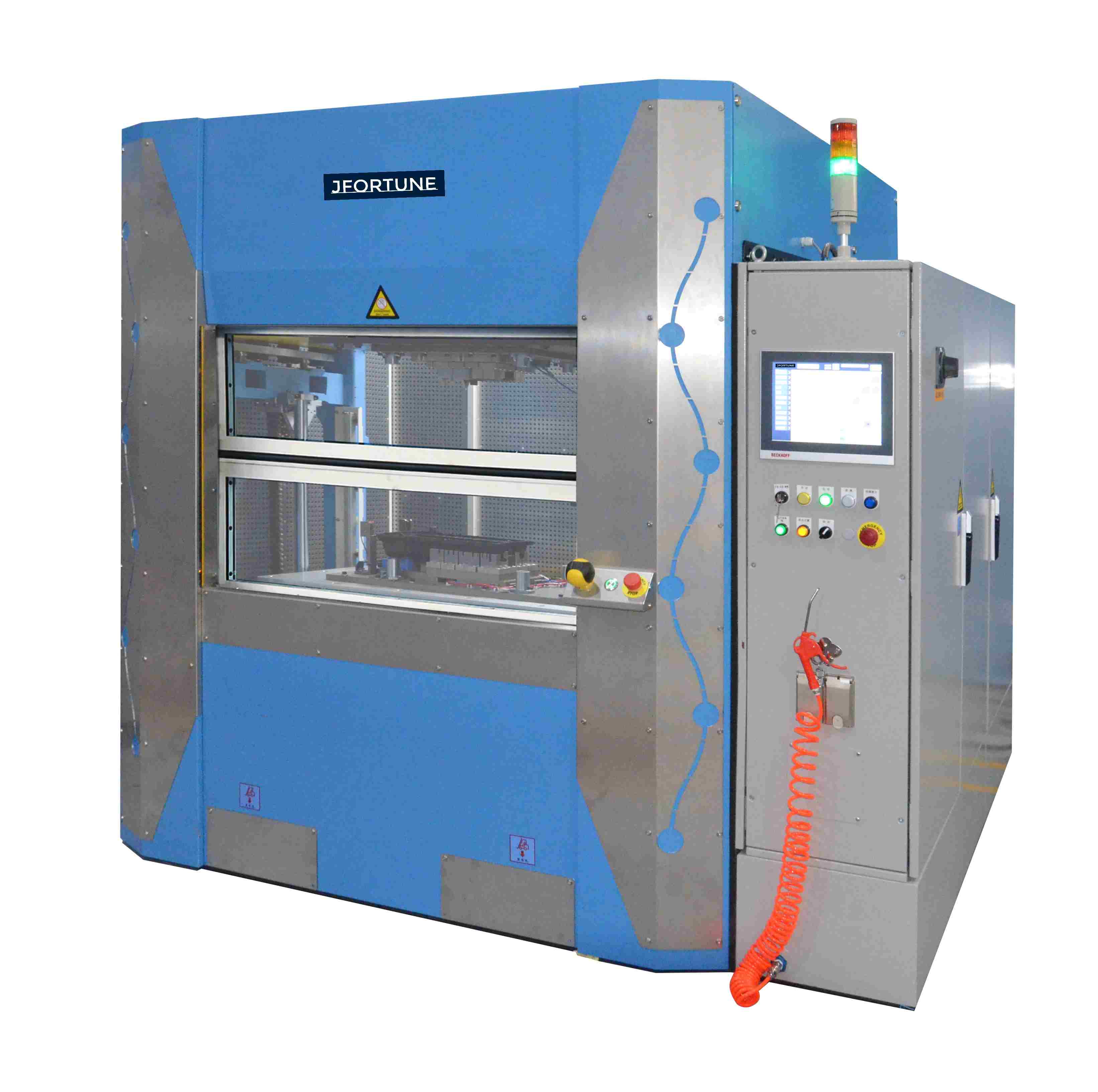

Please read the following carefully before installing and using the vibration welding machines:

Vibration welding machines play a crucial role in the manufacturing process, ensuring the efficient joining of materials through controlled oscillations. However, like any piece of equipment, these machines can be subject to misuse, potentially leading to serious consequences. In this article, we’ll delve into specific instances of improper use and highlight the importance of adhering to safety guidelines to prevent accidents and equipment damage.

The No-Storage Rule

One common misuse scenario involves the improper storage of items on top of the vibration welding machine. It is essential to emphasize that no items should be placed on the equipment, as this can lead to structural issues, collapse, and, in extreme cases, harm to personnel in the vicinity. The vibration welding machine’s design is carefully calibrated to ensure stability during operation, and any added weight on top disrupts this delicate balance.

Safety Door Caution

Another critical point of misuse pertains to the front safety door of the vibration welding machine. The sound insulation cover on the safety door should not be used as storage space for any items. Additionally, personnel should refrain from leaning on or sitting in front of the safety door noise cover. The safety door serves a vital purpose in shielding operators from potential hazards during the welding process.

When the safety door is closed, any items stored on the front sound insulation cover can fall, leading to damage to goods and, more importantly, the risk of injury to personnel. It is essential for operators to understand the potential consequences of such actions and strictly adhere to guidelines to maintain a safe working environment.

Security warning:

1 because of the great weight of the equipment, only a professional person can use such as forklifts to move or install the device.

2 To prevent electric shock, equipment must be reliable grounding, grounding resistance must be in line with local relevant work industry safety regulations, and shall be subject to periodic special inspection.

3 There is high pressure in the presence of vibration power, do not run the equipment in the electric control cabinet door open.

4 The main power supply must be cut off when the parts are replaced or repaired.

5 The vibration welding machines have taken into account the factors of safe operation in the design of any control circuit without the permission of the designer or the modification of a program may result in a false operation which causes the personal injury of the operator.

6 Don’t put the head, hands, and arms in the drive fixture or the working table, the operation of the enormous pressure will cause damage.

7 Because there is pressure in the welding process, after pressing the vibration test key is not to use the hand to touch the vibration movable fixture.

8 In the maintenance or debugging equipment, removal of the safety device, in the maintenance or after the completion of the test must be reset immediately.

![]() 9 It takes about a minute for the capacitor to discharge and to measure the vibration before it is eliminated or repaired. The voltage of the movable power supply confirms that there is no residual current.

9 It takes about a minute for the capacitor to discharge and to measure the vibration before it is eliminated or repaired. The voltage of the movable power supply confirms that there is no residual current.

10 If the equipment is in the presence of possible defects or failures, it can’t be used before being repaired.

Matters need attention:

1 After closing the main power supply for a minute turn on the power supply. Often turning on or off the power supply will cause device failure of the power supply and control circuit.

2 The use of the oil specified in the manual, otherwise it will cause the solenoid valve, oil, hydraulic cylinders, etc. Often to pay attention to the oil and pollutants. When there is oil pollution in the air inlet, the air inlet of the drainage filter must be cleaned.

3 In particular, it is necessary to point out that the upper fixture determines the frequency of vibration, so the weight must satisfy specification requirements. Even if it is well designed, if the quality or strength of the fastening screw is not enough, or there is a tight lack of torque, which can cause the vibration of the head and the vibration power of overload or over amplitude.

4 When changing the installation or replacement, always have to clean the mold, the vibration head, and the surface of the work table.

5 Before starting the vibration head, please adjust the vibration power supply. If it is not adjusted, it may cause vibration head or vibration power failure.

6 Vibration power supply with overload protection circuit. When the vibration or operation of the power supply stops the vibration, please check the mold complies with the requirements of technical specifications, mold installation is correct, whether the mold has cracks, etc.

7 Confirm that the upper and lower fixtures are not in contact with each other, or the upper and lower position sensors, and the depth of the upper and lower fixtures in the process of increasing the working table. The sensor does not touch the working table. Contact will result in damage to the component.

8 When the welding cycle is used in the test to test the vibration, please put the workpiece in the upper and lower fixture, check-up and lower fixture direct contact.

9 Please do not use metal to contact the vibration head or fixture during vibration. Do not start the machine without the fixture, this may cause damage to the power or vibration of the vibrator.

10. Vibration friction welding machine for successful welding, but also depends on a lot of practical applications, such as factors, such as vibration amplitude, pressure, welding time and holding time, design, size and components of welded reinforcement, etc. The changes of these factors in the production process can be changed to obtain the best welding results. Recommended after welding welding good parts carefully examined and tested to ensure their availability.

Important Explain:

1 Open the packing box to install the vibration friction welding machine must be careful to prevent damage to the machine, and need to check if the machine is damaged in transit. If there is damage, please immediately with forwarders or Jfortune local agent contact of the representative. The transport forwarder shall be responsible for the damage or failure caused by the transport process, and shall the transport agent be notified to obtain a claim for any damage or malfunction.

2 Do not allow the vibration of the vibration head or fixture to contact the metal table and other metal parts, or the vibration head and fixtures will be damaged.

3 Do not drive the vibration power when the vibration head is not on the clamp, because it may cause the vibration power failure.

4 The main power supply of the equipment shall be the delta-type three-phase alternating current if the device is not suitable for the power supply. Such as Y-type coupling will cause vibration instability and vibration power failure. When the power supply is insufficient, the preparation will have the same problem.